Advance Processes – Joel Black

Published on 07.04.15

ABAP is a second year module which is focussed on students exploring and testing a specific forge process and annotating, analysing and evaluating their findings in a technical journal. Joel explored pattern welding during this module, here are some his reflections taken from his written evaluation at the end of the module .. “The result

Categories

ABAP is a second year module which is focussed on students exploring and testing a specific forge process and annotating, analysing and evaluating their findings in a technical journal.

Joel explored pattern welding during this module, here are some his reflections taken from his written evaluation at the end of the module ..

“The result of the exercise looks remarkably scientific, like a set of slides laid out in a lab. I found the small pieces of steel difficult to get to grips with (literally), but the polishing was much faster because of the size of the pieces. I still think if i want to explore this further then i will have to get my hands on some 15n20 which is high nickel steel, it resists the etching solution and has a very bright finish but is also hard to get hold of unless i order several tonnes. This, however, is the best way because then one knows exactly how the steel should be treated.

Looking at the samples the wrought iron has a laminated structure naturally so it is not as easy to see the work that went into layering the billets, i think the last row of samples with the carbon steel looks a lot cleaner than the wrought iron. It also made a large difference in the welding of the billets as the wrought iron had lots of impurities that squirt out when welding. Carbon rich steel welds in the fire at a lower temperature, if the heat is controlled well then a very high contrast can be achieved, this requires knowing exactly what is in the steel, a high temp thermometer and a clean burning gas forge. I would like to get my hands on all of the above and do some proper testing.

There are a lot of techniques in pattern welding that I’ve not touched upon: mosaic pattern, powder mosaic patterns but these tend to use very specific materials, for example, powdered steel which can be difficult to get hold of.”

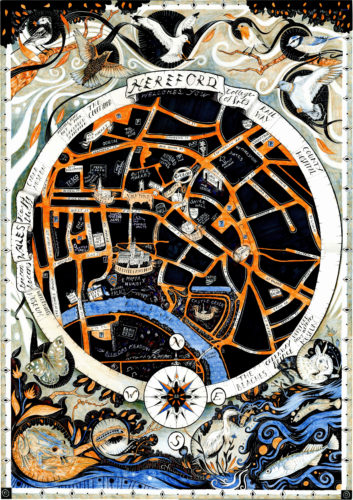

Looking at the picture of all the samples you can see in rows from top to bottom the layers he tested from 9,18,36,72, through to 144 layers and running in the other direction the different patterns he tested , this is an exemplary, detailed and methodical piece of technical research , well done Joel ..

Del